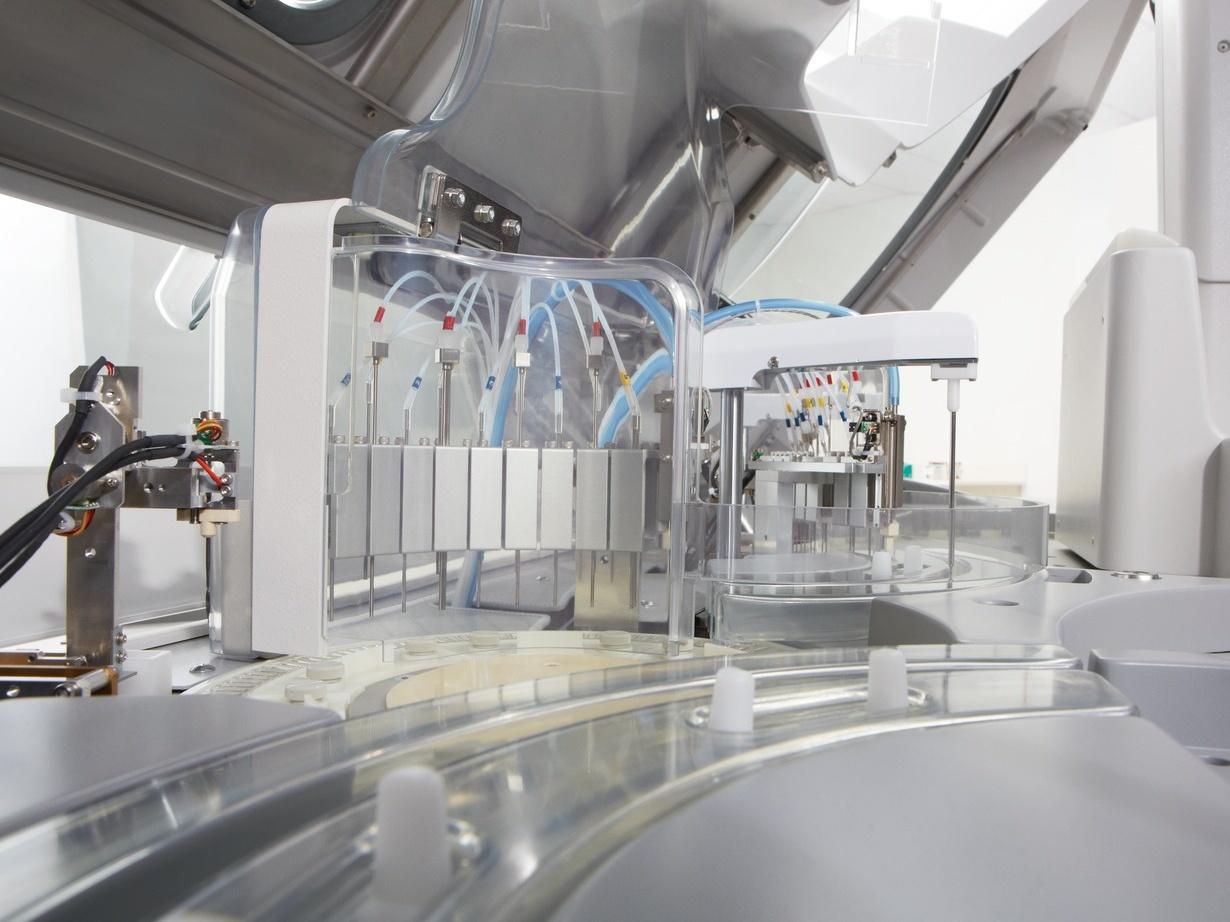

An advanced, automated clinical chemistry analyzer for high-volume laboratories

The ADVIA® Chemistry XPT System provides timely, reliable results with continuous operation to meet the chemistry workloads of the most demanding laboratories.

- Delivers high throughput of up to 2400 tests per hour.

- Manages comprehensive testing with a menu of more than 115 assays.

- Improves workflow using automation and system technologies such as micro-volume and aliquot retention.

Features & Benefits

The ADVIA Chemistry XPT System*** is engineered for continuous operation and timely, accurate results—supporting you to reach your full potential today and be prepared for tomorrow. With an advanced user interface that is easy to use and VeriSmart Technology to support accuracy of testing, the ADVIA Chemistry XPT System predictably and consistently delivers timely, reliable results to meet expanding workloads.

Simplified, Continuous Operation

- Simplify operation and training with the intuitive, icon-driven user interface.

- Extend walkaway times with concentrated reagents that provide high test capacity onboard.

- Quickly load most system fluids on the fly.

- Automate calibration, QC, startup, and shutdown.

Consistent, Predictable Turnaround Time and Accuracy

- Offer a comprehensive chemistry menu of over 115 assays, including general and specialty chemistry, DAT, TDM, and specific proteins.

- Push productivity with a throughput of up to 2400 tests per hour (1800 photometric, plus 600 ISE).

- Control testing: STAT and specialty samples can always be front-loaded while an automation track is running.

Designed for Automation

- Adapt and grow with direct connectivity to Siemens Healthineers Aptio® Automation and ADVIA Automation Solutions.

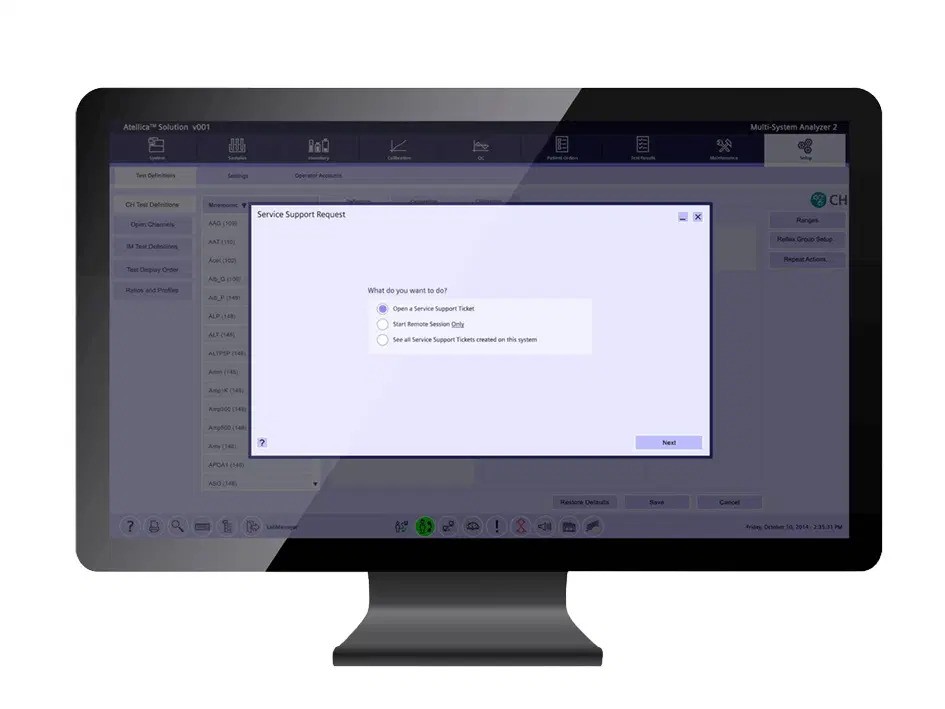

- Simplify your laboratory operations with connectivity to IT solutions including Atellica Process Manager, and Smart Remote Service (SRS).

- Increase productivity and efficiency with direct-from-track sampling and onboard aliquoting allowing samples to be immediately released to the next workstation.

Technical Specifications

|

Product Specifications |

|

|

System Description |

Fully random and continuous access, discrete processing clinical chemistry system with batch run capability |

|

Test Throughput |

Up to 2400 tests/hour: 1800 tests/hour photometric, 600 tests/hour ISE |

|

Assays Onboard |

59, including 3 ISE (Na, K, Cl) |

|

Sample Handling |

|

|

Sample Tubes |

5 mL, 7 mL, and 10 mL tubes; 1 mL and 2 mL sample cups; user-defined containers |

|

Sample Tray |

84 sample positions; positive sample identification |

|

Validated Sample Types |

Serum, plasma, urine, whole blood, and CSF, assay-dependent |

|

Sample Integrity Control |

Qualitative check for hemolysis, lipemia, and icterus; clot detection, flagging, and management; short-sample detection, flagging, and management |

|

STAT Handling |

84 positions, not dedicated; STAT samples are processed with priority |

|

Auto-repeat Testing |

Automatic repeat testing from the retained prediluted sample or original sample |

|

Sample Dilution |

Automatic dilution up to 1:5625 from retained prediluted sample or original sample |

|

Auto-reflex Testing |

Automatic ability to perform additional tests based on results of first test or test combination |

|

Primary Sample Probe |

Liquid-level sensing, crash protection, clot/clog detection, liquid-surface verification |

|

Sample Carryover Prevention |

Automated wash; additional automated sample probe washes programmable for greater prevention |

|

Sample Throughput |

Up to 200 tubes per hour with ISE use; faster without ISE use |

|

Bar Codes |

|

|

Sample Bar Codes |

Up to 20 digits; Interleaved 2 of 5, Code 39, Code 128, Codabar; A, B, and special characters (.-+/*$%) |

|

Micro-volume Technology |

|

|

Automatic Sample Predilution |

Samples typically diluted 1:5 (30 μL sample + 120 μL saline generates up to 15 tests results); retained for auto-repeat, auto-reflex, or auto-dilution until results are available |

|

Predilution Tray |

120 dilution cuvettes |

|

Sample Volume per Test |

2–30 μL of prediluted sample, equating to 0.4–6.0 μL of original sample per test (varies by assay) |

|

Average Reagent Volume |

80–120 μL per test, assay-dependent |

|

Reaction Area |

|

|

Reaction Cuvettes |

340 reusable optical-grade plastic cuvettes |

|

Reaction Bath |

Inert fluorocarbon oil circulation system, 37°C |

|

Photometer |

14 fixed wavelengths (340, 410, 451, 478, 505, 545, 571, 596, 658, 694, 751, 805, 845, and 884 nm) |

|

Light Source |

12 V, 50 W halogen lamp, cooled by forced water circulation |

|

Assay Result Calculations |

Endpoint (EPA), rate reaction (RRA), 2-point rate (2PA), constant rate analysis (CRA), and immunoassay analysis (IMA) methodologies; prozone checking; substrate depletion check; results available as completed |

|

Reaction Times |

3, 4, 5, and 10 minutes; extended reaction times 15 and 21 minutes |

|

Automatic Correction |

Sample blank, cuvette blank, measurement point change, sample volume change in re-assay |

|

Point Forwarding |

Can automatically extend linearity to measure samples over assay range |

|

Assay Technology |

Potentiometric, photometric, turbidimetric |

|

Reagent Handling |

|

|

Reagent Tray |

Two trays, (R1:=60 and R2: =56 positions), refrigerated between 6–13°C (43–55°F) |

|

Onboard Reagent Capacity |

56 photometric assays |

|

Onboard Test Capacity |

40,000 photometric tests average; over 100,000 photometric tests with use of concentrated reagents |

|

Reagent Containers |

20, 40, 70 mL reagent wedges |

|

Reagent Integrity Control |

Bar-code reagent identification; automatic inventory tracking and flagging; calibration and control validity tracking and flagging; reagent onboard stability tracking and flagging; reagent expired/reagent low flagging |

|

Onboard Stability |

Up to 60 days, depending on assay |

|

Reagent Dilutions |

Capability to dilute concentrated reagents onboard |

|

Open-system Capability |

|

|

Channels |

200 assay channels; includes 50 channels for user-defined applications |

|

Ion-selective Electrodes (ISE) |

|

|

ISE |

Indirect simultaneous measurement of Na+, K+, Cl- |

|

ISE Sample Volume |

22 μL original sample for all three tests |

|

Electrode Expected Use Life |

30,000 samples or 3 months, whichever occurs first |

|

Throughput Rate |

Up to 600 tests/hour; 200 tubes/hour |

|

Calibration/QC |

|

|

Validated Calibration Interval |

Up to 60 days, tracked by software |

|

Auto-calibration |

User-defined time interval or with new reagent container |

|

Auto-QC |

User-defined test count interval or with auto-calibration |

|

View Calibration |

Graphical display of calibration curves |

|

QC Data |

Graphical display of QC; real-time/QC monitoring; advanced QC package includes Levey-Jennings plots, Westgard rules, and RiliBÄK rules; 125,000 control results can be stored, archivable to removable media |

|

Calibration/Control Tray |

61 refrigerated positions for calibrators, controls, and diluents |

|

User Interface/Data Management |

|

|

Monitor |

22-inch (55.9 cm) diagonal high-resolution LCD touchscreen with adjustable height |

|

Operating System |

MICROSOFT WINDOWS 10 |

|

System Documentation |

Operator manual, quickstart guide, and online help |

|

Data Storage |

500,000 active plus 500,000 historical test results; can archive to removable media |

|

Onboard Maintenance Logs |

Yes |

|

Host Interface |

TCP/IP bidirectional |

|

Host Query |

ASTM; system requests work order or batch of work orders from host |

|

Remote Access and Service |

Smart Remote Services via 1000BASE-T Ethernet port |

|

Removable Media |

|

|

Removable Media |

DVD, CD-RW, or USB |

|

General Specifications |

|

|

Power Requirements |

200–240 V at 50/60 Hz, 3 kVA consumption |

|

Water Requirements |

CLSI Clinical Laboratory Reagent Water or equivalent connected directly to a pressurized water source |

|

Maximum Water Consumption |

40 liters (10.6 gallons) per hour |

|

Drain Requirements |

Minimum of 40 liters (10.6 gallons) per hour |

|

Dimensions |

With monitor: 149 (h) x 177 (w) x 99 (d) cm; 59 (h) x 70 (w) x 39 (d) inches |

|

Weight |

725 kg (1598 lb) |

|

Compliance |

Complies with international environmental, health, and safety standards, including CE and RoHS |

|

Noise Emission |

Less than 62 dB |

|

Processing Heat Output |

5374 BTU/hour |

|

Ambient Temperature |

18–30°C (64°-86°F) |

|

Ambient Humidity |

20–80% noncondensing |